The Top 10 Most Commonly Replaced Parts on Scissor Lifts (and How to Spot Wear)

1. Batteries

Why they fail: Frequent charging cycles and deep discharges shorten battery life.

Signs of wear: Shorter run times, slow lift movement, corrosion around terminals.

Pro tip: Check fluid levels (if applicable) and keep batteries fully charged after each use.

2. Hydraulic Hoses

Why they fail: Constant pressure and bending cause cracks or leaks.

Signs of wear: Oil spots under the machine, visible cracks, or “spongy” lift response.

Pro tip: Replace at the first sign of leakage to prevent costly cylinder or pump damage.

3. Control Box / Joystick

Why they fail: Heavy use, moisture, and accidental impacts.

Signs of wear: Unresponsive controls, jerky movements, or intermittent power.

Pro tip: Keep control boxes covered when not in use to avoid water damage.

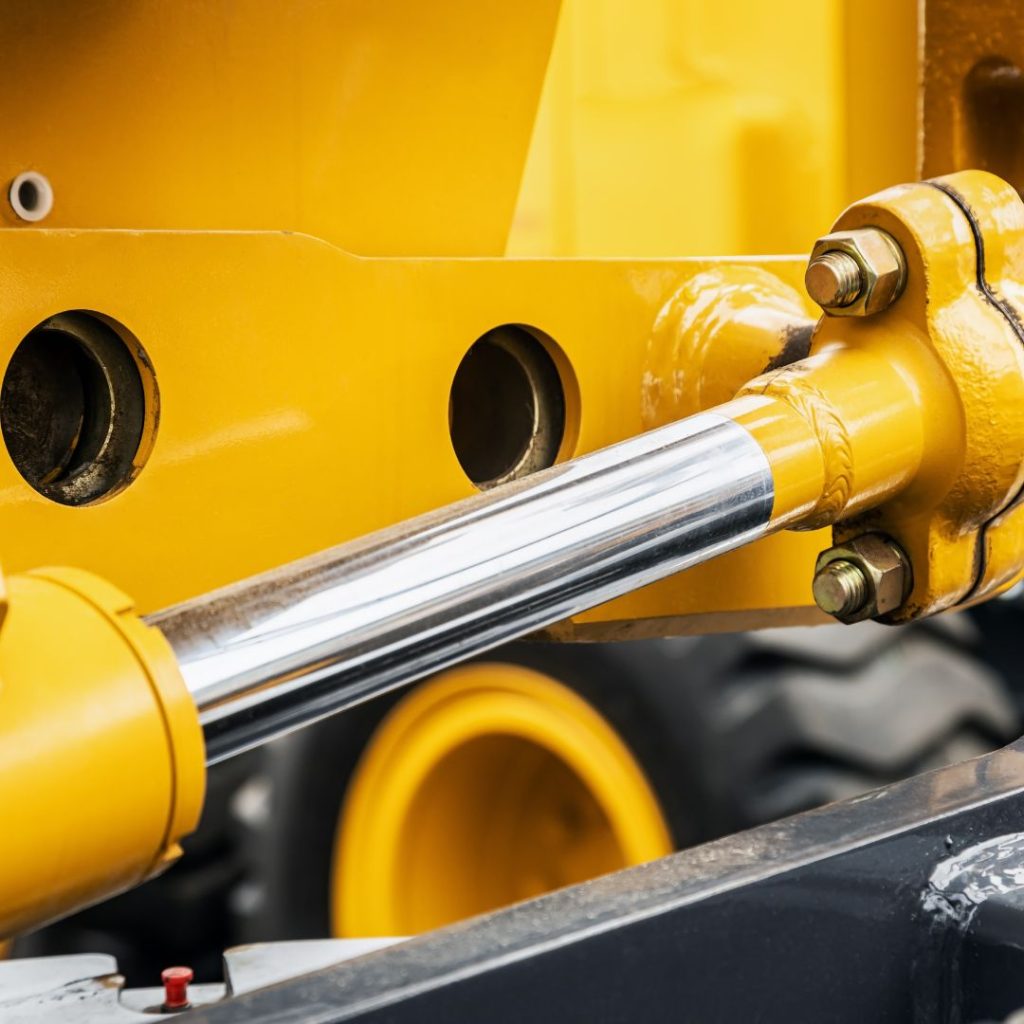

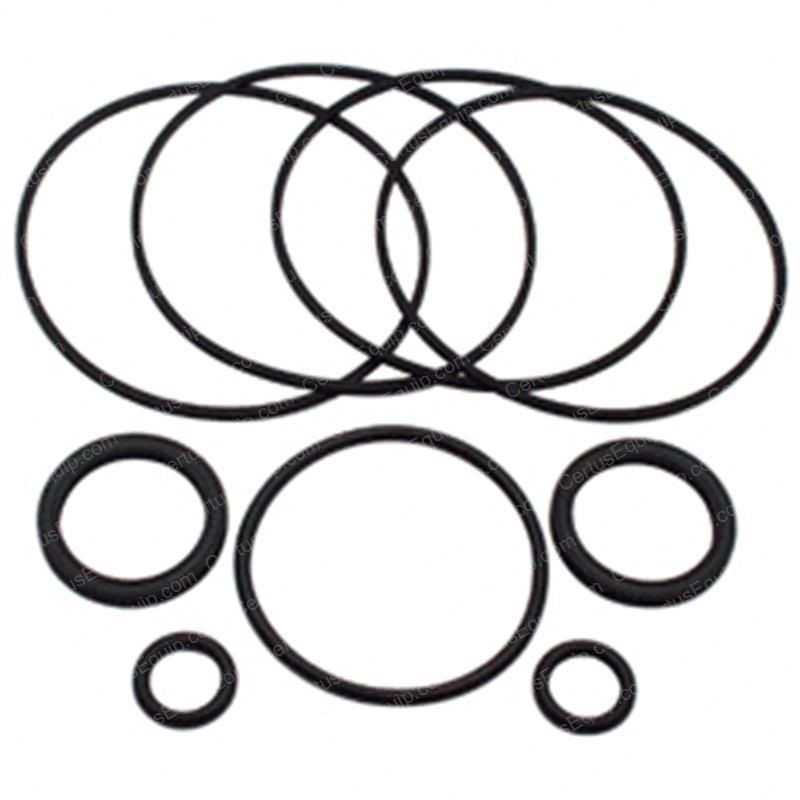

4. Hydraulic Cylinders (Lift Cylinders)

Why they fail: Constant travel on rough terrain or carrying heavy loads.

Signs of wear: Bald treads, cracks in solid tires, or difficulty steering.

Pro tip: Always match tire type (non-marking, rough terrain, solid) to your work environment.

5. Wheels & Tires

Why they fail: Constant travel on rough terrain or carrying heavy loads.

Signs of wear: Bald treads, cracks in solid tires, or difficulty steering.

Pro tip: Always match tire type (non-marking, rough terrain, solid) to your work environment.

6. Drive Motors

Why they fail: Overuse, lack of lubrication, or electrical issues.

Signs of wear: Loss of speed, uneven driving, or grinding noises.

Pro tip: Regularly clean around the drive motor to prevent dust buildup.

7. Contactors / Relays

Why they fail: Arcing from frequent on/off cycles.

Signs of wear: Clicking but no movement, intermittent starting, or burnt smell.

Pro tip: Replace contactors at the first sign of hesitation—they’re cheap compared to motor repairs.

8. Platform Controls (Switches & Sensors)

Why they fail: Heavy operator use and exposure to dust/water.

Signs of wear: Buttons not responding, safety alarms not triggering.

Pro tip: Test safety interlocks regularly—these are critical for OSHA compliance.

9. Steering Components

Why they fail: Wear in linkages, pins, or cylinders.

Signs of wear: Difficult turning, uneven tire wear, or squeaking.

Pro tip: Lubricate pivot points to extend life.

10. Chargers

Why they fail: Overheating, power surges, or cable wear.

Signs of wear: Battery not charging fully, overheating charger, frayed wires.

Pro tip: Keep chargers dry and stored in clean areas—dust and water shorten their life.

Final Thoughts

By keeping an eye on these 10 most commonly replaced scissor lift parts, you can: Extend the life of your equipment

Extend the life of your equipment Reduce costly downtime

Reduce costly downtime Improve operator safety

Improve operator safety

If you’re looking for OEM or aftermarket scissor lift parts, we stock thousands of items ready to ship.